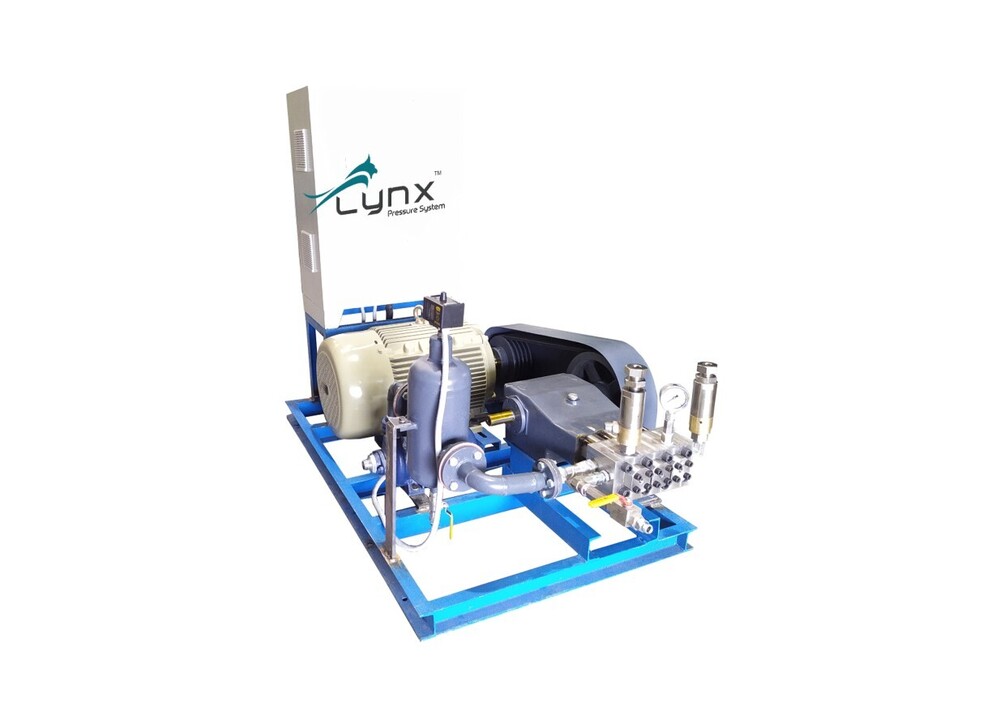

High Pressure Hydrostatic Test Pumps

Product Details:

- Color Standard

- Usage Hydro Pressure Testing, High Pressure Water Jet Cleaning, Washing, Industrial Tube Cleaning

- Product Type High Pressure Reciprocating Triplex Plunger Pumps

- Flow Rate 9 LPM to 20 LPM

- Head Size Forged 304 / 316

- Theory Reciprocating Pump

- Material Standard

- Click to View more

High Pressure Hydrostatic Test Pumps Price And Quantity

- 1 Set

High Pressure Hydrostatic Test Pumps Product Specifications

- 9 LPM to 20 LPM

- Positive Displacement Reciprocating Pump

- High Pressure Reciprocating Triplex Plunger Pumps

- Other

- Diesel

- High Pressure

- Piston Pump

- Electric

- Standard

- Hydro Pressure Testing, High Pressure Water Jet Cleaning, Washing, Industrial Tube Cleaning

- Reciprocating Pump

- Standard

- Forged 304 / 316

High Pressure Hydrostatic Test Pumps Trade Information

- All over India, Mumbai, Mundra, Pipavav

- 5 Set Per Week

- 1 Week

- Contact us for information regarding our sample policy

- Wooden box with plastic wrapping, Export packaging, as per client demand

- South America Western Europe Australia North America Eastern Europe Central America Middle East Asia Africa

- Pondicherry Dadra and Nagar Haveli Tripura Manipur Himachal Pradesh East India Assam Arunachal Pradesh Bihar Chandigarh Delhi Goa Jammu and Kashmir Jharkhand Karnataka Maharashtra Mizoram Meghalaya Punjab Rajasthan Sikkim Telangana West Bengal Andaman and Nicobar Islands Nagaland Daman and Diu Uttarakhand Lakshadweep Uttar Pradesh Haryana Gujarat Tamil Nadu South India Madhya Pradesh North India Andhra Pradesh Kerala Central India Odisha West India Chhattisgarh All India

- MSME, IE

Product Description

- A hydrostatic test pump is a device used to test the strength and integrity of pipes, tanks, valves, and other pressure vessels by subjecting them to high-pressure water. The pump pressurizes the vessel with water to a predetermined pressure and holds it for a specified amount of time while the vessel is visually inspected for leaks or deformations.

- Hydrostatic testing is an essential part of quality control in many industries, including oil and gas, chemical, and power generation. It ensures that pressure vessels can withstand the pressures they are designed to handle, minimizing the risk of catastrophic failure and ensuring the safety of workers and the environment.

- There are various types of hydrostatic test pumps available in the market, ranging from manual hand pumps to electrically powered pumps. Some pumps are portable and can be easily moved from one location to another, while others are stationary and designed for use in a specific location.

- When using a hydrostatic test pump, it is crucial to follow the manufacturer's instructions carefully to ensure the safety of the operator and the equipment being tested. It is also essential to wear appropriate personal protective equipment, such as gloves and safety glasses, when operating the pump.

Hydrostatic Test Pump Features:

Hydrostatic test pumps come with various features that make them useful for different applications. Here are some common features of hydrostatic test pumps:

- Pressure capacity: Hydrostatic test pumps are available with different pressure capacities, ranging from a few hundred PSI to several thousand PSI. The pump's pressure capacity should be chosen based on the maximum pressure the vessel being tested can handle.

- Pumping capacity: The pumping capacity of a hydrostatic test pump determines how quickly it can pressurize the vessel being tested. A high pumping capacity can reduce the testing time, while a low pumping capacity may require longer testing times.

- Power source: Hydrostatic test pumps can be powered by electricity, gas, or manual operation. Electric pumps are typically more powerful and faster than manual pumps, while gas-powered pumps offer more portability.

- Control features: Some hydrostatic test pumps come with advanced control features, such as digital displays, pressure gauges, and automatic shut-off valves. These features can help to ensure that the testing process is accurate and efficient.

- Portability: Portable hydrostatic test pumps are designed to be easily transported from one location to another. They may come with built-in wheels or handles for easy movement.

- Durability: Hydrostatic test pumps should be made from high-quality materials that can withstand exposure to water, pressure, and other environmental factors. Stainless steel and aluminum are common materials used in pump construction.

- Safety features: Hydrostatic test pumps should have safety features, such as pressure relief valves, to prevent over-pressurization of the vessel being tested. The pump should also be designed to prevent backflow of water or other fluids, which could damage the pump or cause injury to the operator.

Hydrostatic Test Pump Applications:

Hydrostatic test pumps are widely used in many industries to test the integrity and strength of pressure vessels and piping systems. Here are some common applications of hydrostatic test pumps:

- Oil and gas industry: Hydrostatic test pumps are commonly used in the oil and gas industry to test the strength of pipelines and pressure vessels used in oil and gas exploration, drilling, and transportation.

- Chemical industry: In the chemical industry, hydrostatic test pumps are used to test the integrity of pipes and tanks used to store and transport chemicals. This is important to ensure that there are no leaks that could result in environmental contamination or worker exposure to hazardous chemicals.

- Power generation: Hydrostatic test pumps are used in power plants to test the strength of pressure vessels and piping systems used in steam turbines, boilers, and other equipment. This is important to ensure that the equipment can withstand the high pressures and temperatures required for power generation.

- Construction industry: In the construction industry, hydrostatic test pumps are used to test the integrity of water mains, fire hydrants, and other piping systems used in buildings and infrastructure projects.

- Aerospace industry: Hydrostatic test pumps are used in the aerospace industry to test the strength and integrity of fuel tanks and other pressure vessels used in aircraft and spacecraft.

- Automotive industry: In the automotive industry, hydrostatic test pumps are used to test the integrity of fuel tanks, radiators, and other pressure vessels used in vehicles.

Overall, hydrostatic test pumps play a critical role in ensuring the safety and reliability of pressure vessels and piping systems in many industries.

BHP Series Model Selection Chart:

|

Model |

SPM |

Flow (LPM) |

Max. Rated Pressure-kg/cm2 (MOTOR-HP) |

Transmission |

|||

|

BHP12 |

730 |

9 |

1200(30) |

1000(25) |

800(20) |

600(15) |

Pulley & Belt Drive |

|

540 |

7 |

1200(25) |

1000(20) |

800(15) |

600(12.5) |

Pulley & Belt Drive |

|

|

420 |

5 |

1200(20) |

1000(15) |

800(12.5) |

600(10) |

Pulley & Belt Drive |

|

|

BHP14 |

730 |

13 |

1000(40) |

800(30) |

600(25) |

400(15) |

Pulley & Belt Drive |

|

BHP16 |

730 |

17 |

750(40) |

600(30) |

500(25) |

- |

Pulley & Belt Drive |

Frequently Asked Questions:

1. What is the maximum pressure capacity of a hydrostatic test pump?

Answer: The maximum pressure capacity of a hydrostatic test pump can vary depending on the model and manufacturer. It can range from a few hundred PSI to several thousand PSI.

2. How do I choose the right hydrostatic test pump for my application?

Answer: When choosing a hydrostatic test pump, consider the pressure capacity and pumping capacity required for your application. You should also consider the power source, control features, portability, durability, and safety features of the pump.

3. How often should I perform hydrostatic testing?

Answer: The frequency of hydrostatic testing depends on the industry and specific equipment being tested. In general, it is recommended to perform hydrostatic testing on pressure vessels and piping systems at least once a year.

4. How do I perform a hydrostatic test?

Answer: To perform a hydrostatic test, the vessel being tested is filled with water, and the pump is used to pressurize the vessel to a predetermined pressure. The pressure is held for a specified amount of time, and the vessel is visually inspected for leaks or deformations.

5. Can I use a hydrostatic test pump to test gases instead of liquids?

Answer: No, hydrostatic test pumps are designed to test the strength and integrity of vessels and piping systems using liquids, typically water. They are not suitable for testing the strength of gas-containing vessels or systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free