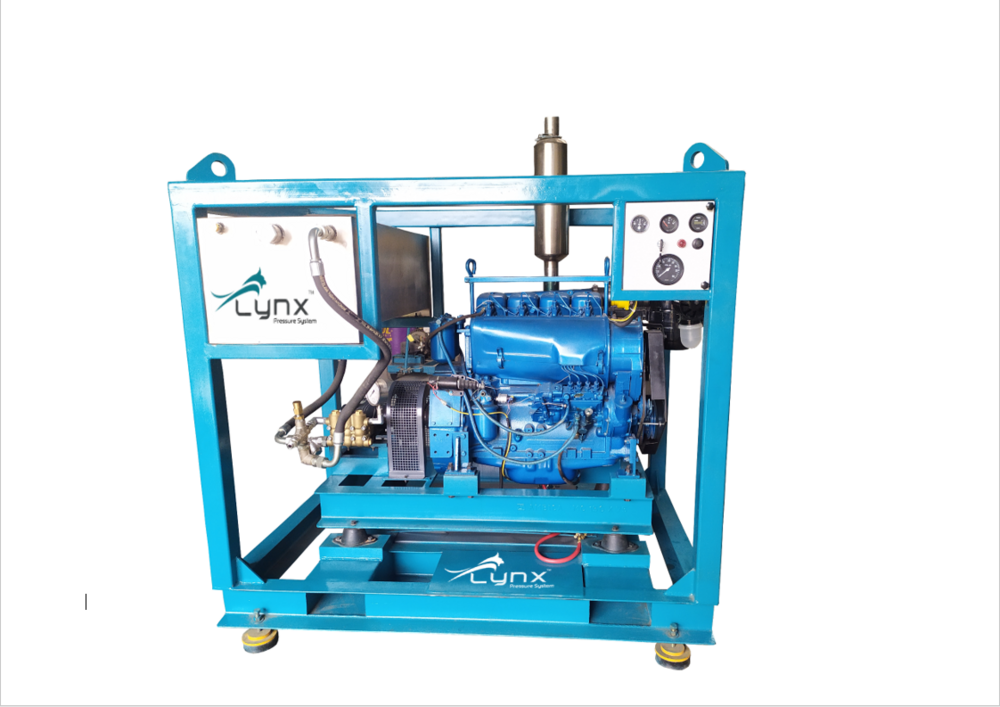

Water Jet Blasting Machines

Product Details:

- Color Blue

- Size Standard

- Product Type Triplex High Pressure Plunger Pumps System

- Usage Industrial

- Power 30 Horsepower (HP)

- Voltage 220-440 Volt (v)

- Click to View more

Water Jet Blasting Machines Price And Quantity

- 285000 INR/Set

- 1 Set

Water Jet Blasting Machines Product Specifications

- Blue

- 220-440 Volt (v)

- 30 Horsepower (HP)

- Industrial

- Triplex High Pressure Plunger Pumps System

- Standard

Water Jet Blasting Machines Trade Information

- Ahmedabad

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cheque

- 75 Set Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden box with bubble plastic wrapping, Export packaging, As per client demand.

- Australia, Eastern Europe, Western Europe, Middle East, South America, Central America, North America, Asia, Africa

- Dadra and Nagar Haveli, Meghalaya, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Lakshadweep, South India, Madhya Pradesh, North India, East India, Andhra Pradesh, Central India, Jharkhand, Chhattisgarh, Himachal Pradesh, All India

- MSME, IEC

Product Description

Water Jet Blasting Machine can effectively remove a wide variety of tough dirt in difficult-to-reach points or locations in a safe and efficient manner. In fact, the results are comparable to those of cleaning techniques that use abrasives and cleaning agents, but without the dust and other health hazards, which allows the workers to focus on their daily tasks in a health-friendly workplace environment.

We Lynx Pressure System are manufacturer of Water Jet Blasting Machines in Ahmedabad; Gujarat; India.

We also export Hydro Blasting Machine to many countries such as UAE, South Africa and many more....

HAWK Pump PXI model selection chart:

|

MODEL |

FLOW |

PRESSURE |

POWER |

|||

|

LPM |

GPM |

PSI |

BAR |

HP |

KW |

|

|

PXI |

15 |

4 |

7250 |

500 |

20 |

15 |

|

5440 |

375 |

15 |

11.18 |

|||

|

4715 |

325 |

12.5 |

9.32 |

|||

|

PXI |

21 |

6 |

7250 |

500 |

30 |

22.37 |

|

5800 |

400 |

25 |

19 |

|||

|

4785 |

330 |

20 |

15 |

|||

Water Blasting Cleaning Applications:

- High Pressure Cleaning

- Tank & Vessel Cleaning

- Hydro Blasting

- Hydro demolition

- Paint Removal

- Ship Hull Cleaning

- Heat Exchanger-Condenser-Boiler-Evaporator Tube & Surface Cleaning

- Surface Preparation

- Textile Industrial Work for Humidification

- Clean and test pressure of petrol pipeline, chemical container, reaction kettle, and heat exchanger by salt work

- Pharmaceutical factory and concrete removal and roughening

- Remove sand, oil, rust, colloid, paint and dirty stuff of castings

- Remove bread crust in rotary kiln of cement plant

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free