Trusted company that deals in quality-made products

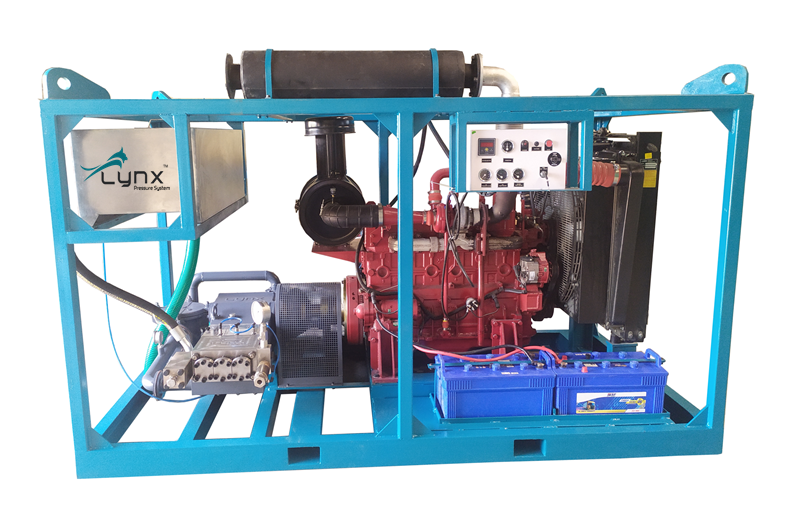

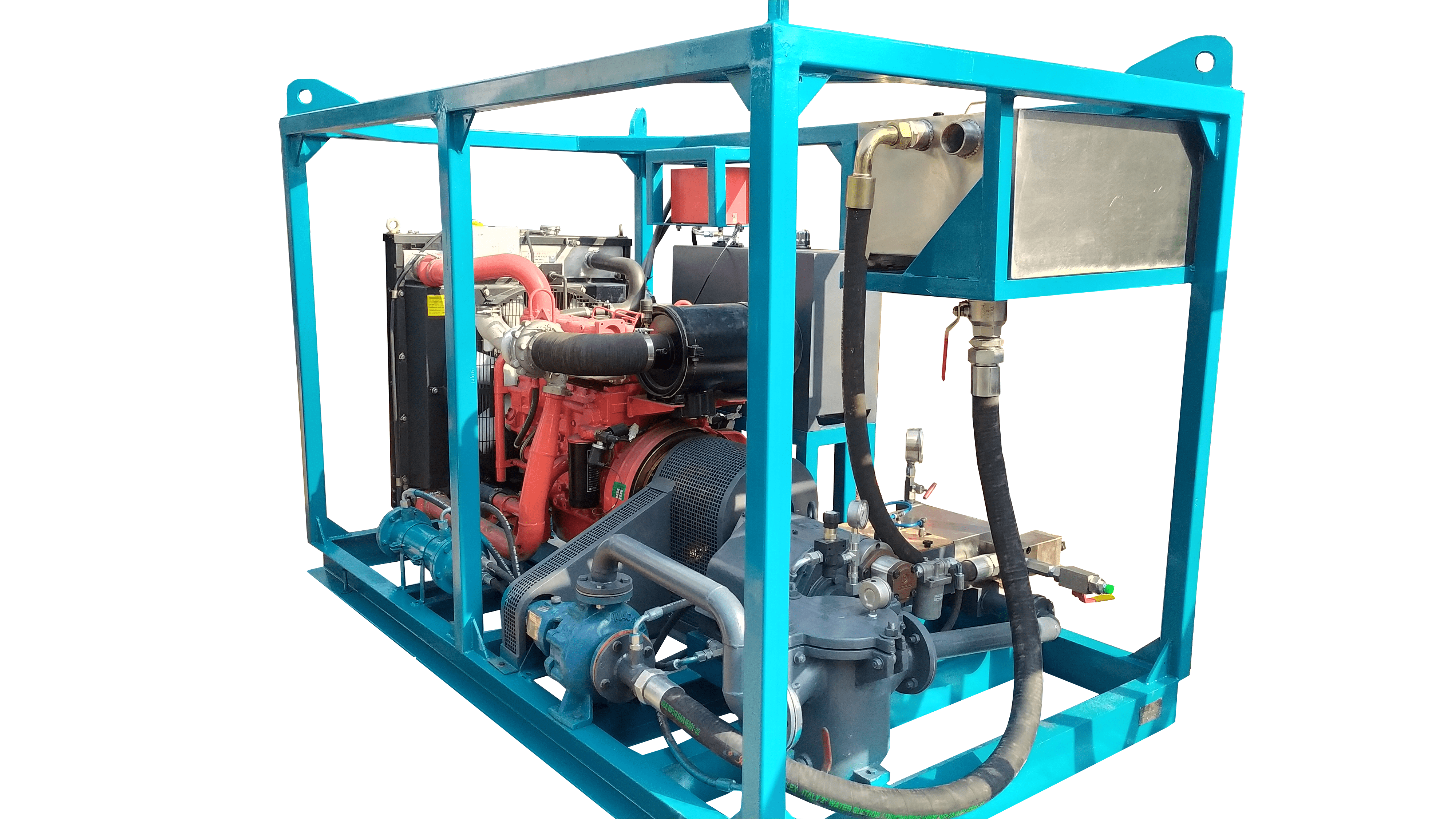

High Pressure Hydro Jetting Machines

283355.00 INR/Piece

Product Details:

- Product Type High Pressure Hydro Jetting Machines

- Color Blue

- Theory Reciprocating Pump

- Usage Industrial

- Structure Piston Pump

- Power Electric

- Fuel Type Diesel

- Click to View more

X

High Pressure Hydro Jetting Machines Price And Quantity

- 1 Piece

- 283355.00 INR/Piece

High Pressure Hydro Jetting Machines Product Specifications

- Industrial

- Electric

- Diesel

- Blue

- Reciprocating Pump

- High Pressure

- High Pressure Hydro Jetting Machines

- Other

- Piston Pump

High Pressure Hydro Jetting Machines Trade Information

- Telegraphic Transfer (T/T)

- 5 Piece Per Week

- 1 Week

- Wooden boxes with bubble plastic wrapping, Export packaging, As per client demand.

- Chandigarh Himachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Dadra and Nagar Haveli Lakshadweep Meghalaya Jammu and Kashmir Andhra Pradesh Delhi East India Tripura West India Goa Maharashtra Haryana Punjab Arunachal Pradesh Manipur Pondicherry Tamil Nadu Telangana West Bengal Mizoram Karnataka Sikkim North India Rajasthan Assam Madhya Pradesh Jharkhand South India Nagaland Gujarat Bihar Kerala Central India Odisha Chhattisgarh Uttar Pradesh All India

Product Description

High Pressure Hydro Jetting Machine, also known as Water-Blasting and sometimes Water-Cutting, is the use of a Hydro Jet that forces highly compressed and pressurized water out of a small hole or nozzle, which causes restriction and produces a high-pressure water stream. This water stream is so powerful it will cut through grease, ice and even concrete, hence it is an effective and precise tool used in many industries.

When correctly applied, high pressure hydro jetting machine can provide acceptable levels of cleaning without damaging anti-fouling coatings or releasing toxins to the environment, but this requires fairly accurate control of jet angle and distance from the surface, and duration of impingement. In other circumstances water jetting can be used to remove paint. Water jetting can be applied manually by divers, by diver-operated carts, or by ROVs. Pressures of between 350 and 1400 bar may be used in high-pressure water jetting.

Applications of High Pressure Hydro Jetting Machines:

1. Drain and Sewer Cleaning: Hydro jetting is widely used for clearing clogged drains and sewer lines. The high-pressure water stream can break up and remove blockages such as grease, sludge, tree roots, and debris, restoring proper flow.

2. Industrial Pipe Cleaning: Industries often use hydro jetting to clean pipes, tubes, and industrial equipment. This is important for maintaining efficient operations and preventing corrosion and scale buildup.

3. Surface Cleaning: Hydro jetting can be used to clean various surfaces, such as buildings, concrete, sidewalks, and parking lots. The high-pressure water stream can remove dirt, grime, graffiti, and paint.

4. Tube and Heat Exchanger Cleaning: In industrial processes, it's essential to keep heat exchangers, condenser tubes, and pipes clean to maintain optimal heat transfer efficiency. Hydro jetting is used to remove deposits and fouling from these components.

5. Paint Removal: Hydro jetting is an effective method for removing paint from surfaces, making it useful in applications such as graffiti removal and repainting preparation.

6. Tank Cleaning: Tanks and containers in various industries need periodic cleaning to remove residues and contaminants. Hydro jetting can effectively clean tanks, eliminating the need for manual cleaning.

7. Ship Hull Cleaning: Cleaning ship hulls is essential to maintain fuel efficiency and prevent the buildup of marine fouling. Hydro jetting can efficiently remove barnacles, algae, and other marine organisms.

8. Deburring and Cutting: High-pressure water jet cutting is used to cut through materials like metal, glass, and ceramics. It's a precise and clean method, making it suitable for applications where traditional cutting methods may cause damage.

9. Concrete Demolition and Hydrodemolition: Hydrodemolition is a technique used to remove deteriorated concrete from structures without causing damage to the surrounding material. It's commonly used in construction and repair projects.

10. Surface Preparation: Before applying coatings or performing welding, hydro jetting can be used to prepare surfaces by removing contaminants, rust, and old paint, ensuring better adhesion.

11. Agricultural and Land Cleaning: Hydro jetting can be employed in agriculture to clean farm equipment, livestock areas, and for land clearing applications, such as removing vegetation or preparing land for construction.

12. Water Jet Propulsion: In some marine vessels and industrial systems, water jet propulsion systems are used for propulsion and steering.

FAQ:

Q. What is high-pressure hydro jetting?

Ans: High-pressure hydro jetting is a cleaning and material removal process that uses a powerful stream of water at high pressure to clear clogs, clean surfaces, cut materials, and remove debris from pipes, tanks, and various other applications.

Q. How does a hydro jetting machine work?

Ans: A hydro jetting machine pressurizes water and propels it through a specially designed nozzle at extremely high pressure. The high-pressure water stream is directed at the target area, effectively breaking down and removing obstructions, residues, or contaminants.

Q. What is the pressure range for hydro jetting machines?

Ans: Hydro jetting machines typically operate at pressures ranging from 1,500 to 40,000 psi (pounds per square inch) or even higher, depending on the specific application.

Q. What are the common applications for hydro jetting machines?

Ans: Common applications include drain and sewer cleaning, industrial pipe cleaning, surface cleaning, tube and heat exchanger cleaning, paint removal, tank cleaning, ship hull cleaning, concrete demolition, deburring, and more.

Q. Is hydro jetting environmentally friendly?

Ans: Hydro jetting is considered environmentally friendly because it uses high-pressure water as the cleaning medium, eliminating the need for harsh chemicals or abrasive materials. It's a more sustainable and non-toxic cleaning method.

Q. Is hydro jetting safe for pipes and surfaces?

Ans: Hydro jetting is generally safe for pipes and surfaces when used correctly. Professional operators ensure that the equipment and pressure levels are appropriate for the specific application to prevent damage.

Q. Can hydro jetting remove tree roots from pipes?

Ans: Yes, hydro jetting is effective at removing tree roots that have infiltrated pipes. The high-pressure water stream can cut through and flush out roots, restoring proper flow.

Q. Is hydro jetting suitable for all types of blockages?

Ans: Hydro jetting is effective for many types of blockages, but it may not be suitable for some pipe materials or extremely fragile obstructions. A professional assessment is recommended to determine the best approach.

Q. How often should hydro jetting be performed for maintenance?

Ans: The frequency of hydro jetting for maintenance depends on the specific application and the rate of buildup or clogs. Some systems may require annual or semi-annual cleaning, while others may need it less frequently.

Q. Are there safety precautions when using hydro jetting machines?

Ans: Yes, safety precautions are crucial when using high-pressure hydro jetting machines. Operators should wear appropriate protective gear, and the equipment should be used in compliance with safety guidelines to prevent accidents.

Q. Can hydro jetting remove hazardous materials or chemicals?

Ans: Hydro jetting can remove many materials, but hazardous materials or chemicals should be properly handled and disposed of according to relevant regulations. The cleaning process itself may not neutralize or eliminate hazardous substances.

Q. Can hydro jetting be used for DIY purposes?

Ans: While smaller, consumer-grade hydro jetting equipment is available, it's often recommended to hire professionals for safety and effectiveness, especially for complex or large-scale applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free