Trusted company that deals in quality-made products

Water Blasting Nozzles

100000.00 INR/Set

Product Details:

- Color Sliver

- Product Type Water Blasting Nozzles

- Usage Industrial

- Structure Piston Pump

- Power Electric

- Pressure High Pressure

- Click to View more

X

Water Blasting Nozzles Price And Quantity

- 100000.00 INR/Set

- 1 Set

Water Blasting Nozzles Product Specifications

- Piston Pump

- Water Blasting Nozzles

- High Pressure

- Industrial

- Electric

- Sliver

Water Blasting Nozzles Trade Information

- 5 Set Per Week

- 1 Week

- Chandigarh Himachal Pradesh Sikkim South India North India East India West India Andaman and Nicobar Islands Andhra Pradesh Assam Arunachal Pradesh Bihar Delhi Daman and Diu Gujarat Goa Haryana Jammu and Kashmir Jharkhand Karnataka Kerala Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Nagaland Punjab Pondicherry Rajasthan Telangana Tripura Uttar Pradesh Uttarakhand West Bengal Dadra and Nagar Haveli Lakshadweep All India Tamil Nadu Central India Odisha Chhattisgarh

Product Description

With an aim to satisfy our clients with quality products, we are working with diligence in order to manufacture, export and supply the best grade Water Blasting Nozzles. These nozzles are manufactured at our well-equipped premises using excellent quality raw materials and contemporary techniques. Especially used for installation in water blasting equipment as important utility for spraying water, the offered nozzles are made available in different sizes, patterns and finishes. Moreover, our clients can avail the offered nozzles at marginal prices from us.

Water Blasting Nozzle Features:

- High-pressure capability: Water blasting nozzles are designed to withstand high pressure, typically ranging from 10,000 to 40,000 PSI, depending on the application.

- Durability: Water blasting nozzles are made from materials that can withstand the high pressure and abrasion of water jet blasting, such as tungsten carbide or ceramic.

- Versatility: Water blasting nozzles are available in various sizes and shapes to accommodate different applications and surface materials.

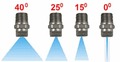

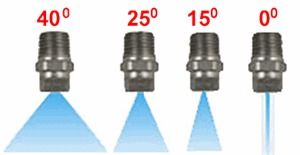

- Stream pattern: Water blasting nozzles can produce different stream patterns, such as a fan, cone, or pinpoint, depending on the nozzle design and application requirements.

Water Blasting Nozzle Applications:

- Surface preparation: Water blasting nozzles are used in surface preparation applications, such as removing rust, paint, and coatings from metal surfaces.

- Concrete cutting and demolition: Water blasting nozzles can be used for cutting and demolishing concrete structures, such as bridges, dams, and buildings.

- Pipe cleaning: Water blasting nozzles can be used for cleaning pipes and removing blockages in sewage systems and industrial pipelines.

- Mining and construction: Water blasting nozzles are used in mining and construction applications, such as tunneling, quarrying, and rock breaking.

- Aerospace and automotive industries: Water blasting nozzles can be used for cleaning and stripping surfaces in the aerospace and automotive industries, such as aircraft and vehicle parts.

Overall, water blasting nozzles are essential tools for high-pressure water jet blasting applications and offer versatility, durability, and high-pressure capability for various applications.

Frequently Asked Questions:

1. What is the working principle of water blasting nozzles?

Ans: Water blasting nozzles work by increasing the velocity and pressure of water as it passes through the nozzle orifice. This high-pressure water jet is then directed towards the surface to be cleaned, cut, or demolished.

2. How do you choose the right water blasting nozzle for your application?

Ans: The choice of water blasting nozzle will depend on the specific application, including the required pressure, flow rate, and surface material. It's important to consult with a supplier or manufacturer to ensure that you choose the right nozzle for your application.

3. What are the common types of water blasting nozzles?

Ans: There are many different types of water blasting nozzles available, including rotating nozzles, flat fan nozzles, cone nozzles, and pinpoint nozzles. Each type of nozzle is designed to produce a specific stream pattern and velocity to suit different applications.

4. What materials are water blasting nozzles made from?

Ans: Water blasting nozzles are typically made from materials that can withstand high pressure and abrasion, such as tungsten carbide, ceramic, or stainless steel.

5. How do you maintain and replace water blasting nozzles?

Ans: Water blasting nozzles should be regularly inspected and cleaned to prevent blockages and ensure optimal performance. Worn or damaged nozzles should be replaced promptly to avoid further damage to the equipment or surface being cleaned.

6. What safety precautions should be taken when using water blasting nozzles?

Ans: Water blasting nozzles can be dangerous if not used properly. Operators should be trained on the safe use and handling of nozzles, including proper PPE, and should follow all safety guidelines and precautions outlined by the manufacturer. It's also important to ensure that the equipment is properly maintained and inspected to prevent accidents and injuries.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free