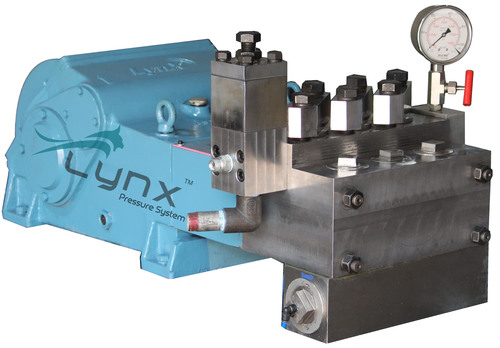

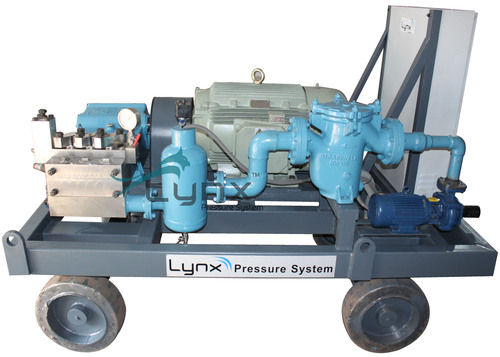

Triplex Reciprocating Pump

Product Details:

- Usage Industrial

- Theory Reciprocating Pump

- Product Type Triplex Reciprocating Pump

- Structure Piston Pump

- Power Electric

- Fuel Type Gasoline

- Pressure Low Pressure Bar

- Click to View more

Triplex Reciprocating Pump Price And Quantity

- 450000.00 INR/Set

- 1 Set

Triplex Reciprocating Pump Product Specifications

- Submersible

- Electric

- Industrial

- Positive

- Gasoline

- Low Pressure Bar

- Piston Pump

- Triplex Reciprocating Pump

- Reciprocating Pump

Triplex Reciprocating Pump Trade Information

- 5 Set Per Week

- 1 Week

- Dadra and Nagar Haveli Himachal Pradesh South India North India East India West India Assam Bihar Chandigarh Goa Haryana Jammu and Kashmir Jharkhand Karnataka Madhya Pradesh Maharashtra Mizoram Punjab Rajasthan Tamil Nadu West Bengal Lakshadweep Meghalaya Arunachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Uttar Pradesh Delhi Gujarat Telangana Andhra Pradesh Kerala Central India Odisha Chhattisgarh All India

Product Description

A triplex reciprocating pump is a type of positive displacement pump that uses three plungers (also known as pistons) to move fluid through the pump. The plungers are typically driven by a crankshaft and connecting rods, which causes them to move back and forth in a reciprocating motion.

As the plungers move back and forth, they draw fluid into the pump through an inlet valve and then push it out through a discharge valve. Because the pump is a positive displacement pump, it delivers a fixed amount of fluid per cycle, regardless of the discharge pressure.

Triplex reciprocating pumps are often used in applications where high-pressure and high-volume fluid pumping is required, such as in oil and gas production, chemical processing, and water treatment. They are known for their reliability and durability, and are capable of handling a wide range of fluids, including corrosive and abrasive materials.

The main advantage of a triplex reciprocating pump is that it provides a smooth, steady flow of fluid with minimal pulsation, which makes it suitable for applications where precise flow control is required. Additionally, triplex pumps are generally more efficient and can deliver higher pressures than duplex pumps, which use two plungers instead of three.

Triplex Reciprocating Pump Features:

- Three plungers: As the name suggests, a triplex reciprocating pump uses three plungers to move fluid through the pump. This design provides a smooth, steady flow of fluid with minimal pulsation.

- Positive displacement: Triplex pumps are positive displacement pumps, which means that they deliver a fixed amount of fluid per cycle, regardless of the discharge pressure. This makes them suitable for applications where precise flow control is required.

- High-pressure capabilities: Triplex pumps are capable of delivering high pressures, up to 10,000 psi (689 bar) or more, depending on the model and configuration. This makes them suitable for applications where high-pressure fluid pumping is required.

- Durable construction: Triplex pumps are known for their durability and reliability, and are designed to handle a wide range of fluids, including corrosive and abrasive materials. They are often made of materials such as stainless steel or high-strength alloys to withstand harsh operating conditions.

- Efficient operation: Triplex pumps are generally more efficient than other types of reciprocating pumps, such as duplex pumps, which use two plungers instead of three. This is because the three-plunger design allows for a more balanced load on the crankshaft, resulting in smoother operation and less wear and tear on the pump components.

- Easy maintenance: Triplex pumps are designed for easy maintenance, with accessible components that can be easily replaced or serviced as needed. Regular maintenance, including lubrication and inspection of valves and seals, is recommended to ensure the pump operates reliably and efficiently.

Key Points of Triplex Reciprocating Pump:

- Offered with Few Moving Parts, Low and Easy Maintenance and Simple & Comfortable Design, Maximum Volumetric Efficiency, rendered with independent alloy steel high wear resistance cylinder.

- Compulsory lubrication system as well as plunger core programmed regulate device, Super-hard alloy or ceramic plunger with all-in-one transmission case.

- Furnished with protection component for phase miscarriage as well as over charge, proffered with intake pressure as well as lubricant pressure warning device.

- Applicative for high Pressure Cleaning, Tank & Vessel Cleaning. Water Sandblasting, Hydro Blasting, Sewer Cleaning.

- Applicative for Pharmaceutical factory as well as concrete removal and roughening, remove oil, rust, colloid, sand paint and dirty material of castings.

Frequently Asked Questions:

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+