Trusted company that deals in quality-made products

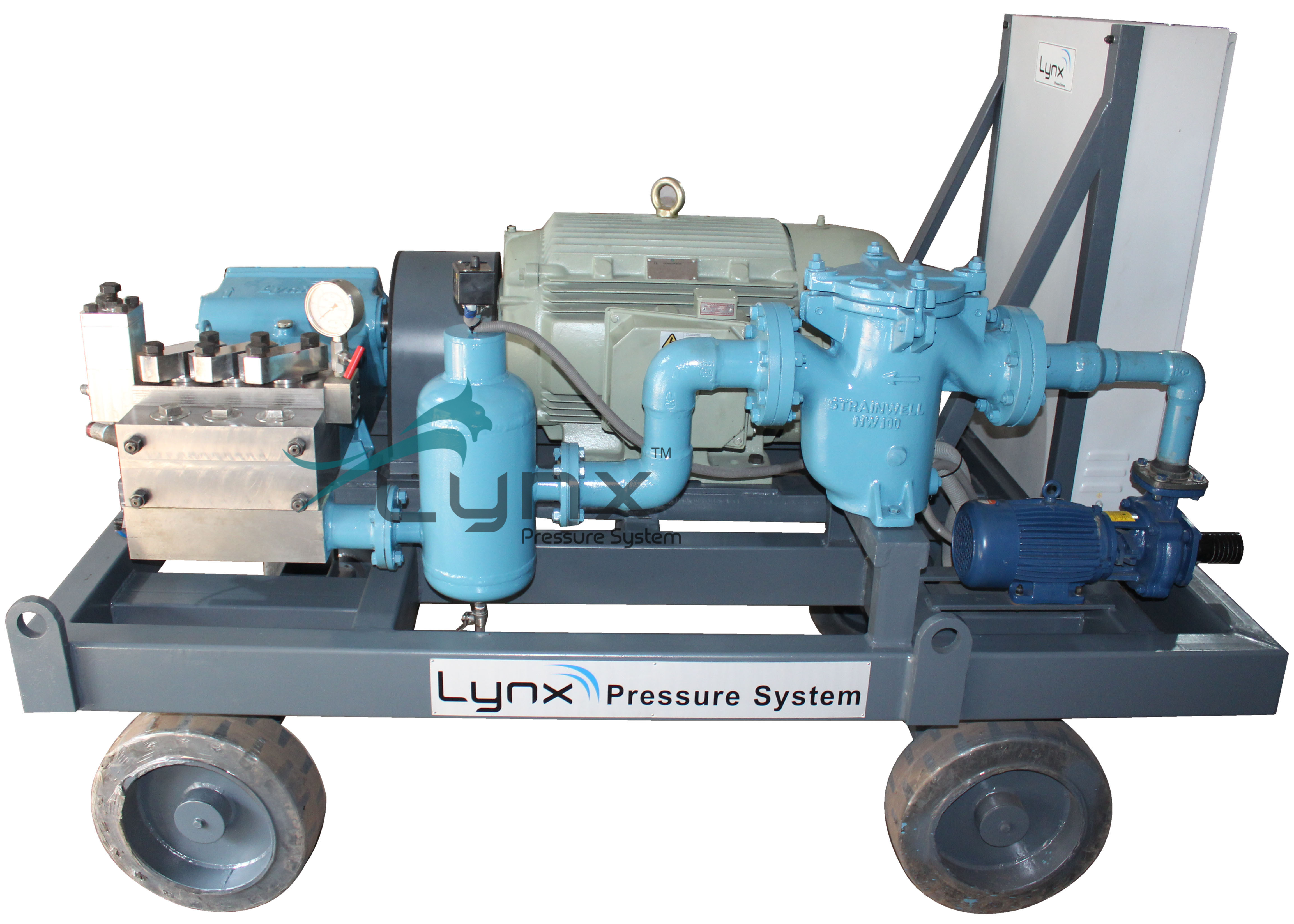

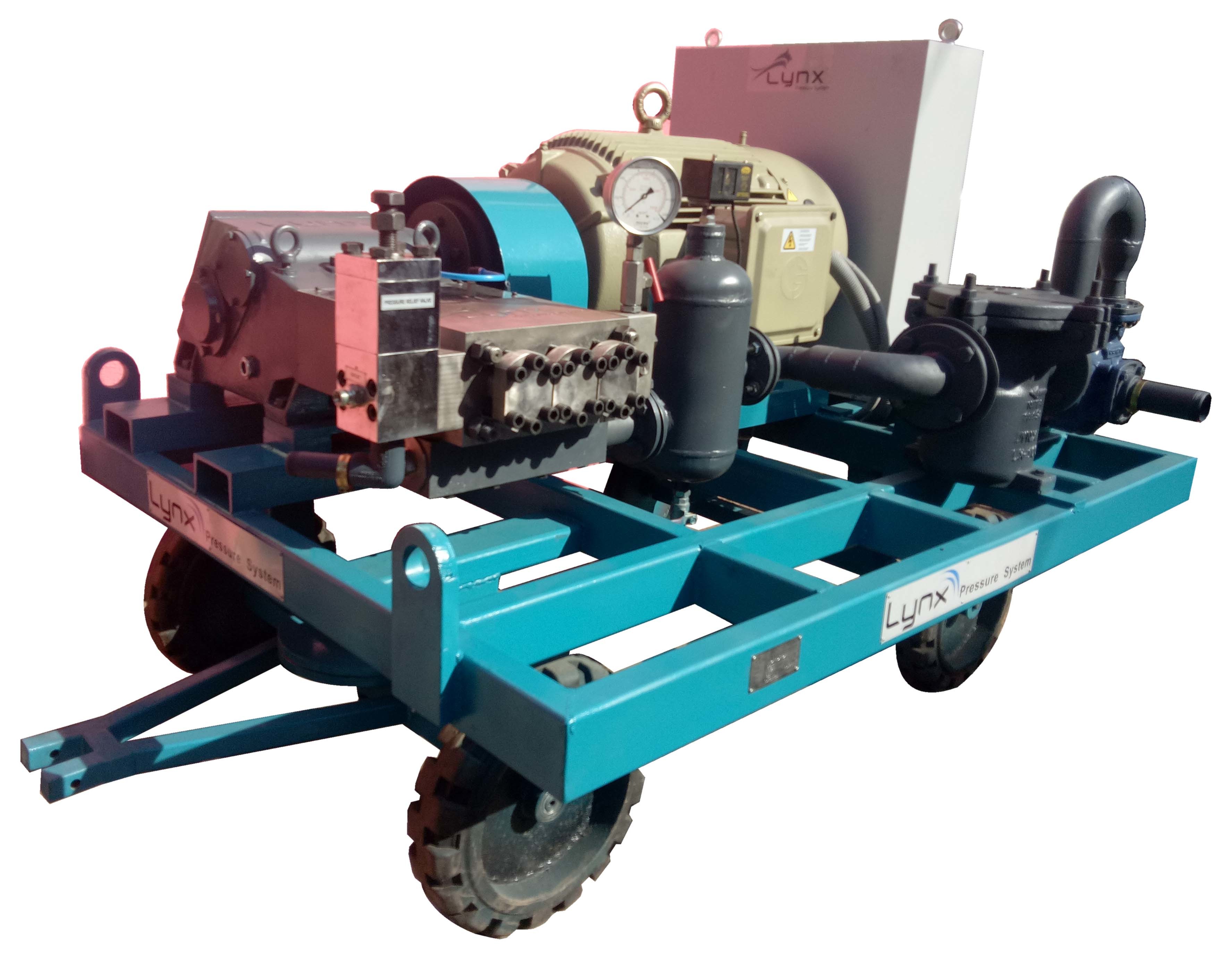

Heat Exchanger Tube Cleaning Machine

650000.00 INR/Set

Product Details:

- Color Blue

- Product Type Heat Exchanger Tube Cleaning Machine

- Usage Industrial

- Condition New

- Fuel Type Electric

- Cleaning Type High Pressure Cleaner

- Voltage 440 Volt (v)

- Click to View more

X

Heat Exchanger Tube Cleaning Machine Price And Quantity

- 1 Set

- 650000.00 INR/Set

Heat Exchanger Tube Cleaning Machine Product Specifications

- 440 Volt (v)

- Heat Exchanger Tube Cleaning Machine

- New

- Industrial

- Blue

- Electric

- High Pressure Cleaner

Heat Exchanger Tube Cleaning Machine Trade Information

- All over India

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Letter of Credit (L/C) Cheque

- 15 Set Per Month

- 7 Week

- Contact us for information regarding our sample policy

- Wooden box with plastic wrapping, Export packaging, As per client demand.

- All India

- MSME, IEC

Product Description

A heat exchanger tube cleaning machine is a device or system designed to clean the tubes of heat exchangers efficiently and effectively. Heat exchangers are used in various industrial processes and HVAC systems to transfer heat from one fluid to another, and over time, the tubes within these heat exchangers can become fouled or clogged with deposits like scale, corrosion, sediment, or biological growth. This fouling reduces the efficiency of heat transfer and can lead to increased energy consumption and maintenance costs.

How does Heat Exchanger Tube Cleaning Machine work?

Heat exchanger tube cleaning machines work by removing deposits and fouling from the inner surfaces of heat exchanger tubes to restore their efficiency and heat transfer capabilities. The specific operation of these machines can vary depending on their type and design. Here's an overview of how different types of heat exchanger tube cleaning machines work:

1. Mechanical Tube Cleaning Machines:

- These machines typically use rotating brushes, scrapers, or cutting tools attached to flexible shafts or rigid rods.

- The cleaning tool is inserted into the heat exchanger tube, and the machine is activated.

- As the tool rotates, it physically scrapes or brushes away deposits such as scale, corrosion, or other solid materials from the tube's inner surface.

- The removed debris is typically flushed out of the tube with a flow of water or another cleaning medium.

2. High-Pressure Water Jet Cleaners:

- Water jet cleaning machines use high-pressure pumps to generate a focused stream of water at high velocity.

- The nozzle of the water jet cleaning machine is inserted into the tube to be cleaned.

- The high-pressure water jet impinges on the tube's inner surface, dislodging and removing deposits.

- The dislodged debris is flushed out of the tube with the water jet and carried away through the heat exchanger's outlet.

3. Chemical Cleaning Machines:

- Chemical cleaning machines use specialized cleaning solutions or chemical agents to dissolve and loosen deposits within the heat exchanger tubes.

- The cleaning solution is circulated through the tubes, allowing it to react with and break down the deposits.

- After a specified dwell time, the chemical solution is flushed out of the tubes using water or another solvent.

- The removed deposits are carried away with the cleaning solution.

4. Ultrasonic Tube Cleaning Machines:

- Ultrasonic cleaners utilize high-frequency sound waves that create vibrations within the heat exchanger tubes.

- These vibrations help to dislodge and break up deposits on the tube's inner surface.

- Cleaning solutions or detergents are often used in conjunction with ultrasonic cleaning to aid in the removal of loosened deposits.

- The cleaning solution and loosened deposits are typically flushed out of the tubes.

The choice of cleaning method and machine depends on factors such as the type and severity of fouling, tube material, and the specific requirements of the application. In some cases, a combination of methods may be used to achieve thorough cleaning.

Regular maintenance and cleaning of heat exchanger tubes are essential for maintaining energy efficiency, preventing equipment damage, and ensuring the continued reliable operation of heat exchangers. Proper safety procedures and equipment manufacturer guidelines should be followed when using these machines, as cleaning may involve high-pressure equipment, hazardous materials, or chemicals.

Applications of Heat Exchanger Tube Cleaning Machine:

Heat exchanger tube cleaning machines find application in various industrial sectors and processes where heat exchangers are used. These machines are essential for maintaining the efficiency and reliability of heat exchangers. Here are some common applications of heat exchanger tube cleaning machines:

1. HVAC Systems: Heat exchanger tube cleaning is crucial in heating, ventilation, and air conditioning (HVAC) systems. Clean tubes ensure efficient heat transfer, which is essential for maintaining indoor climate control in commercial and residential buildings.

2. Power Plants: Heat exchangers play a critical role in power generation facilities, such as steam turbines and cooling systems. Tube cleaning machines are used to prevent fouling, which can reduce the efficiency of heat exchangers and negatively impact power production.

3. Petrochemical Industry: Refineries and petrochemical plants use heat exchangers to transfer heat in various processes. Tube cleaning machines help prevent the buildup of deposits like hydrocarbons, sulfur compounds, and other contaminants in these heat exchangers.

4. Chemical Processing: Heat exchangers are used extensively in the chemical industry. Cleaning machines are essential for removing chemical residues, solids, and corrosive materials from the tubes to maintain process efficiency and product quality.

5. Food and Beverage Industry: Heat exchangers are used in food and beverage processing for pasteurization, sterilization, and cooling. Tube cleaning machines help prevent contamination and maintain hygienic conditions by removing food residues and deposits.

6. Pharmaceuticals: The pharmaceutical industry relies on heat exchangers for processes like sterilization and distillation. Tube cleaning is crucial to ensure product purity and safety.

7. Manufacturing: Industrial manufacturing processes often use heat exchangers to control temperatures in various applications. Cleaning machines are used to maintain the efficiency of these heat exchangers, which can be crucial for product quality and process consistency.

8. Waste Water Treatment: Heat exchangers are employed in wastewater treatment plants for processes like sludge drying and odor control. Tube cleaning machines help prevent fouling from biological and chemical residues.

9. Marine and Shipping: Ships and marine vessels use heat exchangers for engine cooling, HVAC, and desalination systems. Tube cleaning is necessary to prevent fouling in the marine environment.

10. Pharmaceuticals: In the pharmaceutical industry, heat exchangers are used in various processes, including sterilization and distillation. Tube cleaning is vital to ensure product purity and safety.

11. Sugar Refining: Sugar refineries use heat exchangers in various steps of sugar processing. Tube cleaning machines help maintain efficiency and prevent the buildup of sugar deposits and impurities.

12. Pulp and Paper Industry: Heat exchangers are used for cooling and heating processes in pulp and paper mills. Tube cleaning machines help prevent the accumulation of pulp residues and chemicals.

Advantages of Heat Exchanger Tube Cleaning Machine:

Heat exchanger tube cleaning machines offer several advantages for various industries and applications. These machines are essential for maintaining the efficiency and reliability of heat exchangers. Here are some of the key advantages of using heat exchanger tube cleaning machines:

1. Improved Heat Transfer Efficiency: The primary benefit of using these machines is that they help restore and maintain the optimal heat transfer efficiency of heat exchangers. By removing deposits and fouling from the tube surfaces, the machines ensure that heat is exchanged more effectively, which can result in energy savings and improved system performance.

2. Energy Savings: Clean heat exchanger tubes require less energy to achieve the desired temperature differentials. As a result, the operation of heating and cooling systems becomes more energy-efficient, leading to reduced energy consumption and lower operating costs.

3. Extended Equipment Life: Regular cleaning with tube cleaning machines can extend the lifespan of heat exchangers. It reduces the risk of corrosion and damage to the tube materials, which can result from prolonged exposure to fouling and deposits.

4. Prevention of System Downtime: By preventing fouling-related issues, these machines reduce the need for unplanned shutdowns and maintenance. This ensures that heat exchangers remain operational, preventing costly downtime in industrial processes and HVAC systems.

5. Maintained System Performance: Clean heat exchangers provide consistent and reliable performance. This is crucial for industries where process efficiency and product quality are paramount.

6. Reduced Maintenance Costs: Regular maintenance using tube cleaning machines can reduce the need for costly repairs or replacement of heat exchangers. This leads to cost savings in the long run.

7. Improved Air Quality: In HVAC systems, clean heat exchangers help maintain indoor air quality by preventing the growth of mold and the accumulation of particulate matter, which can be harmful to health.

8. Hygienic Conditions: In industries such as food and pharmaceuticals, maintaining clean heat exchangers is essential for ensuring hygienic processing conditions and product safety.

9. Environmental Benefits: Cleaner heat exchangers result in reduced energy consumption and, consequently, lower greenhouse gas emissions, contributing to a more environmentally friendly operation.

10. Flexibility and Versatility: Tube cleaning machines are available in various designs, making them adaptable to different types of heat exchangers and fouling challenges. They can be customized to suit specific applications.

11. Compliance with Regulations: In certain industries, regulatory agencies may require the regular cleaning and maintenance of heat exchangers to meet environmental and safety standards. Tube cleaning machines help businesses comply with these regulations.

12. Safety Improvements: Maintaining clean heat exchangers can reduce the risk of equipment failure or overheating, which can lead to safety hazards in industrial processes.

FAQ:

1. What is a heat exchanger tube cleaning machine?

Ans: A heat exchanger tube cleaning machine is a device or system designed to clean the inner surfaces of heat exchanger tubes, removing deposits and fouling to maintain heat transfer efficiency.

2. Why is cleaning heat exchanger tubes important?

Ans: Cleaning is essential to prevent reduced heat transfer efficiency, increased energy consumption, equipment damage, and downtime. It ensures that heat exchangers operate at their peak performance.

3. What types of deposits can accumulate in heat exchanger tubes?

Ans: Deposits can include scale, corrosion, rust, biological growth, sludge, particulate matter, and various chemical residues, depending on the application and environment.

4. What are the common methods for cleaning heat exchanger tubes?

Ans: Common methods include mechanical cleaning (using brushes or scrapers), high-pressure water jet cleaning, chemical cleaning (using specialized solutions), and ultrasonic cleaning.

5. How do I choose the right cleaning method and machine for my heat exchanger?

Ans: The choice depends on factors like the type of fouling, tube material, and the specific requirements of your application. Consult with a professional or the equipment manufacturer for guidance.

6. How often should heat exchanger tubes be cleaned?

Ans: The cleaning frequency varies depending on the application, but regular maintenance and monitoring are essential. In some cases, an annual or semi-annual schedule may be sufficient, while others require more frequent cleaning.

7. Are there safety considerations when using tube cleaning machines?

Ans: Yes, safety is crucial. These machines may involve high-pressure equipment, hazardous materials, or chemicals. Always follow safety procedures, wear appropriate protective gear, and adhere to manufacturer guidelines.

8. Can heat exchanger tube cleaning machines be used on all types of heat exchangers?

Ans: Tube cleaning machines can be adapted to suit different heat exchanger types and sizes. However, it's essential to ensure that the chosen method and machine are compatible with your specific heat exchanger.

9. Can I perform heat exchanger tube cleaning in-house, or should I hire professionals?

Ans: Whether you can perform cleaning in-house depends on your expertise and the complexity of your system. In some cases, hiring professionals with experience in heat exchanger maintenance is advisable.

10. What are the consequences of neglecting heat exchanger tube cleaning?

Ans: Neglecting cleaning can result in reduced heat transfer efficiency, increased energy costs, equipment damage, and potential safety risks. It can also lead to the need for costly repairs or replacements.

11. Do cleaning methods affect the lifespan of heat exchanger tubes?

Ans: When done correctly, regular cleaning methods can help extend the lifespan of heat exchanger tubes by preventing corrosion and fouling-related damage.

12. Can chemical cleaning damage heat exchanger tubes?

Ans: Properly executed chemical cleaning should not damage tubes. However, it's important to use the correct cleaning agents and follow recommended procedures to avoid potential issues.

13. Are there environmental considerations with heat exchanger tube cleaning?

Ans: Keeping heat exchangers clean can lead to reduced energy consumption and, in turn, lower greenhouse gas emissions, contributing to environmental sustainability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email